Working an Ox with a 3‐Pad Collar

I didn’t know how to answer that question, my mind had stalled at “I’m from Animal Actors.” What the heck was an animal actor? And how did she get my number? I told her I would have to think about it, she said to take my time; she only needed an answer and pictures of the aforementioned oxen in two hours.

So I went and discussed the possibility of a trip to Washington, D.C., in a week with my dad, who also trucks all my livestock. After we got through the initial “you are crazy” stage, I talked him into it using my powers of persuasion and the fact that I promised to pay him well. I found some nice pictures of my best team and sent them off. I would do the job &andash; which, it turned out, was a commercial!

I didn’t know that these jobs go through a bid process, and just because I agreed to go didn’t mean I got the job. I didn’t get a definite answer until Tuesday, and I had to leave three days later. Tuesday was a big day, I also found out they wanted one ox, not two, so I had to round up a harness big enough to fit my 2,000‐pound ox!

I had a friend, Herb Stacey, in Loweville N.Y., who had a single harness, so I called to see if I could borrow it. Herb said I could use it, but he didn’t have it. He had loaned it to Annie Roubilard. I called Annie, she had left the harness at an Amish harness shop because it was too small for her Holstein ox, so they were making another one. I didn’t know the shop owner, and, because they are Amish, I couldn’t call them and explain what I wanted. So my friend Judy Boyer went with me; she knew the owner and we picked up the harness.

When I had the equipment, I had to convince my off ox Sage to wear it. He was very forgiving and adjusted to the single life well. Now we had a single ox, more pictures were sent, and, during those three days, Sage and I practiced and practiced. Then we faced the dilemma of what to do with Bramble. It didn’t seem fair to leave him home, so he went as the stunt double. We went down to Virginia and completed the commercial, and, by the time we were done filming, I was in love with the ox harness. It was so much less complicated than a single yoke and horse harness we were using on our smaller single ox. You lay the harness over the ox’s back and fasten the collar under his neck. You buckle the girth under the belly behind the front legs. I talked to Herb Stacey, and he was nice enough to sell it to me. That was how we acquired our three‐pad collar and harness. Now I will tell you all the reasons why it’s so wonderful!

In my research of the development of the three‐collar and harness I found a paper written by Waclaw Micuta, director of the Renewable Energy Development Institute (REDI) in Geneva, Switzerland. During World War II in Switzerland, the army took all the horses for the war effort, and the few tractors in the country were unable to run with the limited fuel. The people still had to eat, so they started using cattle for the agricultural work and transportation. Most of the cattle used were family milk cows.

With the sudden shift to cattle, there was a need for information. The Swiss authorities conducted research to improve and simplify the traditional cattle harness. The research was published and given to farmers and harness makers. The new design was different than the horse collar that was used earlier. Only the shoulders of the animal were protected with two pads, while a third pad was fixed between the hames to keep the collar in the correct position on the body.

The REDI is trying to develop a harness based on the Swiss design that is cheaper to produce so it can be used in developing countries to increase food production. They have compiled a lot of information on ox harnesses.

These are some of the useful facts I found:

A harness allows the power of the animal to be transferred to the implement. To meet traction requirements, the characteristics of a good harness are: correct angle of pull, surface pressure, working position and weight.

Angle of Pull

Loads are pulled by traces that connect the load to the animal. The angle between the trace and the horizontal line at the point of attachment to the load is called the angle of pull. This angle should be as narrow as possible to use maximum animal power. Ideally, there should be no angle at all, but angles occur – when animals are attached to high carts and the traces are parallel to the ground. As the angle increases, the pulling force is split at the point of attachment to the animal. With the increased angle, part of the pulling force is wasted and exerts pressure and discomfort on the animal.

Surface Pressure

Efficiency of the harness is greatly influenced by the way it fits the animal. With the traditional yoke or log fitted across the neck of the animal, the pulling surface in contact with the animal's body is small. Shocks and bumps during work will increase pressure further and cause discomfort, which may lead to diseases of the skin and open wounds. Animals harnessed in this way are incapable of fully developing their potential draught capacity. With a well‐designed and properly fitted collar, the pulling surface on each shoulder may be increased. The pressure on the animal’s back can be reduced. This, with more padding, allows the animals to work more effectively without suffering.

Working Position

An efficient harness must be designed so the animal can use its body in a natural way. Placing the yoke on the head or neck of the animal alters its natural stance and forces it to curve its spine to hold the yoke in place.

Harness Weight

The harness should be as lightweight as possible.

After I found the Swiss origin of the three‐pad collar and harness, I learned it had been used in Germany much earlier. A research article by Jorg Bremond shows the Germans were really the pioneers of the whole thing.

According to Bremond, Germans have a long history of working cattle. From the 1880s to the 1950s, more than 2 million cows and oxen were used for working animals. Until the 20th century, a variety of harnesses were developed, depending on what materials were available and what farmers could afford. Most of the time, yokes were used to take power and force from the animals, but they were not as effective as they could be.

Bremond goes on to say that Germans developed the three‐pad collar from horse harnesses. The horse harnesses were so efficient they wanted to develop a similar system for cattle. A horse collar is stiff and lies on the horse's chest. The horse's chest remains flat no matter how it moves, so the collar always lies in the correct position. Cattle have different conformation without a flat chest, so the horse collar didn’t fit them well. On cattle, the shoulders are the best place to adjust the collar. When laid on the neck of cattle, the stiff collar constricts movement. Cattle need a flexible collar, so they design the three‐pad collar.

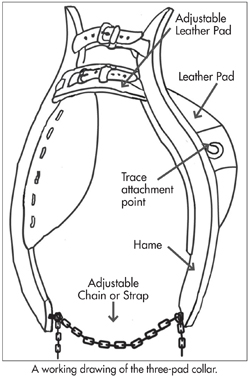

The three‐pad collar has two wooden hames. On each hame, the pad lies on the ox’s shoulder. The third pad is between the two hames to position the collar on the animal's neck. The hames themselves are connected by a leather strap on the top and by a chain, strap, or snap at the bottom. This makes the collar flexible to follow the animals movement. The collar can be adjusted to fit animals of different sizes. The flexibility allows the collar to stay in the right position on the ox’s shoulder so work is efficient.

The Germans give a lot of credit for the development of the collar to a man named Heinrich Steinmetz, who was an agricultural engineer. In 1935 he published a booklet called “Cow‐harnessing in Germany.” It was a complete documentation of cow harnessing at the time and promoted the use of the “adjustable three‐pad collar.”

Cattle were essential for agricultural work until the 1970s. So the recommendations in the booklet were still important for small farms. In the 1930s, the main reasons for the three‐pad system were increased efficiency of farming.

By the 1990s, there were no oxen left in Germany. Dr. Rolf Minhorst took Heinrich Steinmtz’s ideas and published a handbook for improved cattle harnessing. Many people in Germany read the book and started working cattle for historical reasons. With the return of oxen, the three pad collar returned also.

A few facts from the Prairie Ox Drovers website: The pulling surface of a yoke is 200 square cm, while the pulling surface of the harness is 1,200 square cm per shoulder. The harness has more than six times the pulling surface of the yoke. The website also mentioned a study done in France in the 1920s that showed a single harnessed ox could pull the same amount as a yoked team.

After I had all these facts, I wanted to talk to a person who had more first‐hand experience using the three‐pad collar system than I did. So I emailed Drew Conroy, who wrote the book, “Oxen, a Teamsters Guide.” His answer wasn’t what I expected. He said, “Please realize I’m not an expert on that system, and have actually gotten into some pretty good debates about its shortcomings from my perspective.”

I then contacted Dulcy Perkins at Tillers International, but she didn’t have any experience with it either. There is some mention of oxen working in harness on the Prairie Ox Drovers site, but the harness they use has a sweat pad collar that is more like a horse collar. Then I remembered that Klaus Karbaumer, a frequent Front Porch contributor, had mentioned seeing the three‐pad collar and harness used when he was a boy. Now I had a person to talk to!

Klaus grew up in Bavaria, which is in the southeastern part of Germany. He made clear he is not an expert on working cattle; his focus has always been on horses.

Klaus told me that north of the Main River in Germany people had smaller land holdings – only 10 to 12 acres – so oxen were more suited to this scale of operation. This area in the Bavarian forests is also very mountainous, like the Appalachian Mountains, and oxen were preferred. On a trip to visit an uncle in 1961, Klaus counted 30 teams of cows and oxen hitched to implements in a 12‐mile stretch. On the smallest farms, they couldn’t afford to feed an additional animal just for draft work, so most of the labor was done by the family cow. The cattle most often used were Simmentals. In German they are called Bayerisches Hohenfleckvieh, which means highland painted cattle. The Simmentals were considered a three‐purpose cattle: they supplied draft power, milk, and meat. Holsteins were considered Lowland Cattle and were not seen until later, when people started specializing on production.

In all his encounters with oxen, Klaus had never seen a yoke used until he came to the U.S. He said the harnesses were so efficient that no one would consider using a yoke. Germany has strict laws on the prevention of cruelty to animals and even the harnesses are regulated for animal comfort. He is sure that the use of a yoke would be illegal there. It is commonly believed that the yoke sits on the back of the neck and pushes down on the vertebrae, which could harm the ox.

He has a fond memory about a neighbor and his ox that he shared with me. His neighbor, Mr. Lachauer, had a big ox – at least 17 hands at the shoulder (or 68 inches). Every day at noon, the church bell rang signaling lunch. At noon, that ox would go home no matter where he was or what he was doing. Mr. Lachauer would run after him cursing all the way home. After noon, he would go out and work again, but that ox never missed his lunch break.

some work done!

If anyone is interested in buying a three‐pad collar and single ox harness, one place they are being made is the Amish harness shop of Joe Hostetler, US Hwy 812, Rennsselear Falls, NY 13680.

![]()