Shoeing Stocks

The truth is that many horse owners, draft and light, neglect to do the training necessary to have their horses cooperative about their feet being handled. Many horses have a lifetime of hoof neglect because of the difficulty of getting them to submit to foot handling.

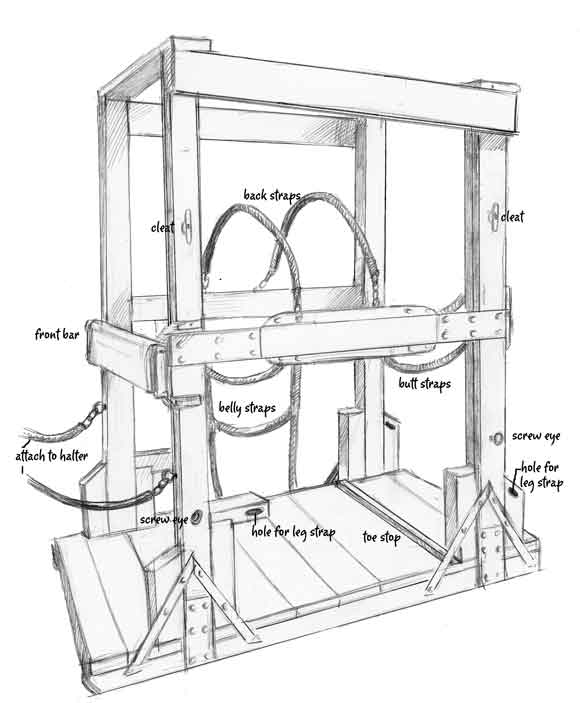

There are many different styles and types of shoeing stocks. The wide variety of stocks is likely the result of different needs, the available building materials, construction skills and available funds. Stocks are basically a stanchion that enables the handler to restrain the horse without hurting the animal or the handlers. Shoeing stocks can be made from welded pipe or angle iron or reinforced rough‐sawn oak lumber. Oxen can also be trimmed and shod by using stocks. Some stocks are stationary affairs, while others can be transported via a flatbed trailer, skid loader or assembled on‐site. Yoder Shoeing Stocks (330‐893‐3102) are made of oak lumber and can be unassembled and moved to new locations. Stationary stocks, of course, mean that the horse must come to you. There are straps or chains for under the horse’s belly and over the back. The foot to be shod then has a strap placed around it and the foot is elevated. The restraining chains include two belly chains, two butt chains and two back chains. Belly chains are needed to prevent the horse from lying down in the stocks. One of the belly chains is situated near the front legs, the other the rear and all these chains should be inside rubber hose for protection. The butt chains hold the horse in the proper forward position in the stocks and the back chains are used to keep the horse from rearing up while in the stocks.

The stocks should always be located on solid, level ground. Stocks are usually designed to be secure while the horse is confined and improper placement can compromise that stability.

If the horse only goes into stocks to be worked on for less than pleasurable actions, he will soon get a bad attitude about getting into the stocks. Spend some time when possible to put the horse into stocks while grooming and graining so the horse has some pleasant experiences with the stocks. Assuming the horse loads into the stocks, the first action is to hook the two butt chains provided on the back of most stocks before tying the horse’s head. Alternate tightening the slack in the chains until the horse is snug against the front chest bar. Horses may try to escape the shoeing stocks by trying to jump the chest bar. To prevent this, immediately fasten the upper front chain. To keep the horse from lying down in the stocks, fasten both lower chains. Lastly, fasten the upper rear chain. The lower chains are adjusted to remove all slack while the upper chains remain looser. Toe stops are a good addition to help keep the horse’s hind feet from sliding forward. Putting a cuff on a rear leg should be done while staying as upright as possible, rubbing your hand slowly down the leg and carefully introducing the cuff. Some difficult horses may kick or resist so use utmost caution when applying the cuffs.

While many horses will pick up their feet easily with a light pull on the cuff rope, resistant horses can be persuaded by pulling the foot to the side instead of up, sliding the foot until the horse offers to raise it on his own. Cupping the toe of the hoof with one hand often relaxes a horse and he will offer less resistance and the foot can be easily moved to the proper position.

Many stocks will have screw eyes or cleats where the cuff rope can be secured to hold the hoof in position. The screw eyes are designed to make a rope pulley from the cuff rope. Running the cuff rope first through the screw eye and back to the cuff ring doubles the lifting power and secures the leg against the stock. The front feet will not need to be drawn close to the upright beam and doing so can twist the joints causing discomfort.

An added advantage of using stocks is that it places the horse about a foot higher off the ground and reduces the amount you have to bend over. When the foot is strapped into place both of your hands are free to work on the hoof without worrying about holding or restraining the animal.

Before taking the horse out of the stocks, remove any and all cuffs before undoing the upper and lower chains. Make sure everything is detached from the horse, before releasing the last butt chain and backing him out.

***How to build shoeing stocks on a skid can be found at www.ruralheritage.com/village_smithy/stock_ skids.htm.

This article appeared in the July/August 2010 issue of Rural Heritage magazine.